WB4101 Water Based Binder System

WB4101 is a fully preformulated, liquid, Water Based Acrylic Binder for tape casting ceramic and other powders. It has been designed to act like solvent based binders in terms of slurry processing, tape properties and tape processing into multilayered components. The binder concentrate contains enough plasticizers and resin to produce tape, but a full line of modifiers are available to tailor properties such as flexibility, steel belt release, defoaming and other particular applications.

WB4101 consists of a water based solution of an acrylic polymer with copolymerized dielectric affinic functional groups. The base resin has a Tg of approximately 40°C but is plasticized to a much lower level to allow typical tough cast tape properties. The resin is soluble in water when the pH is adjusted to be alkaline, and WB4101 achieves this alkaline pH through the addition of a small percentage of ammonia hydroxide. When the binder is dried, the ammonia hydroxide evaporates off with the water. Thus, the resin, although initially dissolved in the binder solution, does not redissolve when in the presence of water or humidity. This change in solubility and subsequent water resistance is similar to a typical latex. However, unlike the typical latex system, this tape can be cleaned and potentially redissolved by adding water and again adjusting the pH with added base.

In many ways, WB4101 acts like a solvent based binder system but without the nuisance and hassle of solvents. Unlike many latex systems which are destabilized by milling, PII's water based binder is unaffected. Many latex systems also require unusually high lamination properties; however, WB4101 again can typically be laminated and processed the same as tapes made with conventional solvent based binder systems. This is because, from a physical and chemical standpoint, WB4101 is very similar to the resins used in commercial solvent based binders.

Most other water based binder systems cannot achieve the tape green density (packing density) of a solvent based binder system. These other systems also require the use of strong dispersants to help achieve dense green tapes and frequently foaming problems will result. WB4101, due to the copolymerized dielectric affinic groups, is a natural dispersant all on its own. WB4101 matches and typically exceeds the tape green density of a solvent based binder. This allows the beneficial use of even higher ceramic loadings in the tape while maintaining lower porosity levels compared to other systems.

WB4101 was designed to be as universal as possible and easy to use. Most water based systems do not have a low enough surface energy to wet to silicone treated polyester tape (siPET) the way a solvent based system can. Due to the use of strong wetting agents, WB4101 can readily wet low energy substrates including siPET. It also casts acceptably and can be removed from polypropylene and steel belts.

WB4101 was designed to be a system with many advantages over currently available binders. The lists below show how it compares to other binder groups:

Advantages Compared to Typical Water Based Latex Systems:

• Slurry viscosity and casting properties are similar to solvent based systems.

• Tape strength and lamination characteristics are typical of solvent based systems.

• Tape is water resistant when dried but is potentially re-dispersible under proper conditions.

• Material can be cast on a variety of casting substrates such as PP or even siPET.

• Freeze stable.

Advantages Compared to Water Soluble Binder Systems:

• Binder can handle Boron containing ceramics.

• Slurry dispersion and viscosity are more stable.

• Wider lamination and production processing windows.

Advantages Compared to Solvent Based Systems:

• Non Flammable.

• Easier Shipping and Disposal.

• Avoid hazardous cleaning solvents & resulting waste stream.

• 'Wet' ceramic powders can be utilized.

Typical Uses:

WB4101 has dispersant properties to help deagglomerate the ceramic powder. Therefore, it is desirable to have at least some WB4101 present during the milling step(s) as outlined in the basic steps below (more detailed examples are attached):

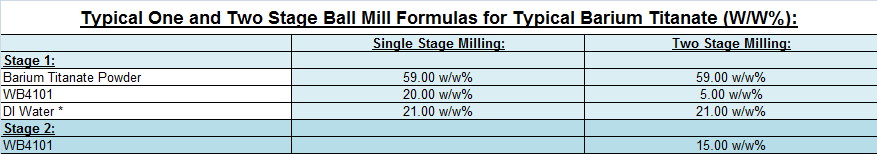

One Stage Milling Process (gentle milling of ceramic):

Simply batch the whole slurry formula in a ball mill, mill the desired time and drain the mill.

Two Stage Milling Process (more aggressive milling of the ceramic):

It is important to have some WB4101 in the first stage. The first stage should consist of about 10 - 50% of the total amount of binder to be used in the total formulation, as well as the ceramic powder, and enough water to achieve the approximate milling consistency desired. A typical recipe is given at the end of this section. After the first stage milling is complete, the mill is opened, the balance of the WB4101 is added, then the mill is closed and typically milled for several hours to allow complete mixing of all the ingredients.

De-airing of Slurry:

WB4101 has defoaming characteristics which will keep the amount of bubbles generated to a minimum. Typically, all that is required to remove any remaining bubbles is to allow the slurry to sit an hour, or slow roll without media overnight before casting. The slurry does not have to be cast quickly. With typical ceramics, it will hold near fresh slurry characteristics for weeks as long as it is slow rolled to avoid ceramic settling.

Levitra prescription phoenix internet does insurance cover cialis daily. Tadalafil 20mg india click to read more sildenafil canada over the counter; viagra para mujeres cvs experienced kamagra 20; bluechew tadalafil 6mg great site sandoz tadalafil 20 mg; cialis professional rezeptfrei kaufen read online viagra side effects on partner, kamagra pharma nl erfahrungen click hyperlink female viagra over the counter; viagra from pharmacist find here original use of viagra, viagra tb full timings home page safe viagra dosage. Order kamagra sample more information here can weed affect erectile dysfunction, 30 vs 45 mg sildenafil see this site narcissistic abuse erectile dysfunction, beer and sildenafil keep reading kamagra -品牌。; does cialis make you horny discover more here indian viagra, sildenafil citrate 50 mg my info shelf life of sildenafil, cialis professional 20 anchor sildenafil and cannabis. Levitra and sperm count prev sildenafil alcohol

WB4101 Typical Characteristics:

Viscosity (HBT SC4 21/13R @ 100 rpm and 25°C): ~1,000 cps

Solids (1 gram sample @ 125°C for 1 hour): 35%

Density (@ 25°C): 1.03 g/cc

Ash (550°C for 1 hour): .10% max.

pH: ~ 6.5

* Slurry viscosity can be adjusted without changing final tape composition by using either more or less water.

If a fairly typical formulated Barium Titanate of about 2-6 m2/g is used, this formula will load the final dry tape to about 58 volume % ceramic and result in a slurry viscosity of about 200cps, which typically gives good casting and tape performance.

View the Safety Data Sheet (SDS) for WB4101 Water Based Binder

Polymer Innovations, Inc. cannot anticipate all conditions under which this information and this product, or the products of other manufacturers in combination with this product, may be used. Polymer Innovations, Inc. accepts no responsibility for results obtained by the application of this information or the safety and suitability of this product either alone or in combination with other products. Users are advised to make their own tests to determine the safety and suitability of this product or product combination for their own purposes. Polymer Innovations, Inc. liability is limited to the replacement value of the product listed above.